Converting the EFI Small Block Ford 302 to Carburetor Considerations

When doing a build like this a few things need to be considered and rectified prior to doing this build. There were small differences between the older ford 302’s and the newer EFi ones. These are the things to notate and fix.

- The timing cover needs to be swapped to a mechanical fuel pump style (read post & see photos here)

- An oil filer adapter needs to be used when converting the explorer or oil cooled H.O. versions (read post & see photos here)

- A fuel pump eccentric and longer cam dowel needs to be added to the cam gear. (read post & see photos here)

- You will need to plug the block oil-dipstick hole with a brass 1/8″ NPT plug and blue RTV. You will also need to RTV and feather the underside of the block. (scroll down to see photos)

- The intake manifold needs to be swapped for a carburetor model.

- The oil pump, pickup, and oil pan need to be swapped to a front sump style (depending on the model your EFI donor came from) (read post & see photos here)

- You need a new dipstick for the timing cover.

The rest of the items you see are pretty straight forward when it comes to building your new 302. Email me with any questions. I will help.

Torque Specifications For Small Block Ford 302

Use these torque specifications as a reference when building your budget 302. When using ARP bolts, follow their specifications always.

| Bolts or Parts | Lube or Sealer | Torque to: |

| Main Caps | Engine Oil | 70 ft-lbs. |

| Outer Main Cap Bolts | Engine | 40 ft-lbs. |

| Connecting Rod 260, 289, 302 | Engine Oil | 25 ft-lbs. |

| Cylinder Heads | Use Sealer | 70 ft-lbs. |

| Rocker Arms | Engine Oil | 20 ft-lbs. |

| Oil Pump | Engine Oil | 25 ft-lbs. |

| Oil Pan | Engine Oil | 15 ft-lbs. |

| Camshaft Thrust Plate | Thread Locker | 10 ft-lbs. |

| Cam Bolt (upper gear) | Thread Locker | 40 ft-lbs. |

| Front Cover | Engine Oil | 20 ft-lbs. |

| Intake Manifold w/ GT40 | Non- Hardening Sealer | 25 ft-lbs. |

| Valve Cover | Engine Oil | 10 ft-lbs. |

| Flexplate (Automatic) | Thread Locker | 85 ft-lbs. |

| Flywheel (Clutch) | Thread Locker | 85 ft-lbs. |

| Clutch Pressure Plate | Thread Locker | 35 ft-lbs. |

| Center bolt (Harm. Balancer) | Thread Locker | 90 ft-lbs. |

| Bellhousing | Engine Oil | 25 ft-lbs. |

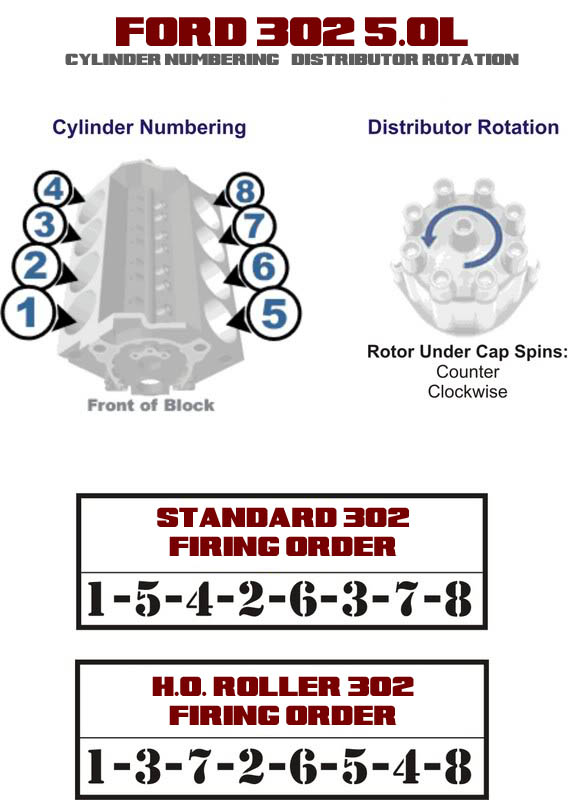

Cylinder Numbering & Distributor Rotation Ford 302

This image is fairly common around the net but is a good reference. You may use the image however you like.

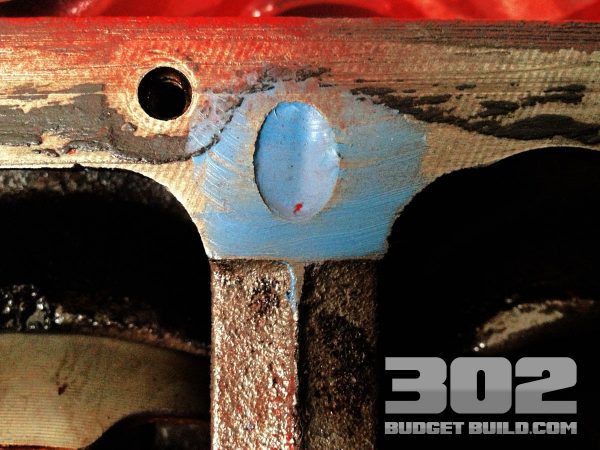

Plugging the engine block oil dipstick hole

These are the steps I take to plug the engine block dipstick hole. This method works and is very inexpensive. This method is permanent and never leaks.

This is a brass NPT 1/8″ plug. Tap the threads and set the plug with RTV on the threads. After, turn the block over and add RTV sealer into the hole and feather out to make a clean finish.

DO NOT: Use a cork, wood, or any other foreign materials. Use a plug and do it right.